<

>

Question: What kind of organization is the Agricultural Machinery Research Laboratory? What are its functions and goals?

answer:

The Agricultural Machinery Research Laboratory is a government departmental institution located within the Agriculture Improvement Station of the Ministry of Agriculture in Taichung, Taiwan. It is dedicated to the research and development of agricultural machinery technology, with the primary goal of improving agricultural production efficiency, reducing labor costs, and enhancing the agricultural production environment to promote the modernization of agriculture.

The main functions of the Agricultural Machinery Research Laboratory include:

Agricultural machinery design and development: Conducting research on new agricultural machinery designs to meet the needs of different regions and crops, and to enhance the adaptability and efficiency of machinery in agricultural production.

Technological innovation and improvement: Improving and innovating existing agricultural machinery technologies to enhance performance, reliability, and service life, meeting the demand of farmers for efficient and convenient agricultural production.

Reduction of agricultural production costs: Researching and developing efficient and labor-saving agricultural machinery equipment to reduce labor costs and energy consumption in agricultural production, thereby increasing agricultural production efficiency.

Integration with agricultural production: Maintaining close contact with rural areas to understand the actual needs of farmers and developing agricultural machinery products that are more closely aligned with practical applications based on field conditions and crop characteristics.

Question: How does the Agricultural Machinery Research Laboratory choose research and development projects?

answer:

The Agricultural Machinery Research Laboratory typically considers multiple factors when selecting research and development projects to ensure that its projects effectively meet the practical needs and challenges of agricultural production. Here are some possible considerations:

Agricultural production demands: The Agricultural Machinery Research Laboratory collaborates closely with farmers and agricultural producers to understand their actual needs and challenges. This may include factors such as types of crops, growing seasons, soil conditions, etc.

Crop area and planting patterns: The Agricultural Machinery Research Laboratory considers the main types of crops and their planting areas in different regions to determine which agricultural machinery technologies can provide the greatest assistance for the production of these crops.

Labor conditions: If a region faces labor shortages or high costs, the Agricultural Machinery Research Laboratory may prioritize the development of machinery equipment that can substitute for manual labor, thus alleviating labor pressure.

Technological feasibility: The Agricultural Machinery Research Laboratory evaluates the feasibility and cost-effectiveness of different technologies to determine which research projects are likely to be realized and can bring significant benefits in practical applications.

Environmental protection requirements: Considering the importance of environmental protection, the Agricultural Machinery Research Laboratory may prioritize the development of low-carbon, energy-saving, and environmentally friendly agricultural machinery equipment to reduce negative impacts on the environment.

In summary, the Agricultural Machinery Research Laboratory comprehensively considers various factors when selecting research and development projects to ensure that its projects effectively meet the practical needs of agricultural production and promote agricultural modernization and sustainable development.

Question: In addition to developing machines, how can the Agricultural Machinery Research Laboratory help farmers?

answer:

In addition to developing new agricultural machinery equipment, the Agricultural Machinery Research Laboratory can also assist farmers through other means to enhance their productivity and technical skills:

Agricultural machinery subsidy programs: Machinery developed by the Agricultural Machinery Research Laboratory undergoes technical authorization to manufacturers. The laboratory also assists in conducting performance tests for agricultural machinery, obtaining qualification certificates, and then including them in agricultural machinery subsidy programs. Through subsidy policies, farmers can more easily acquire and utilize efficient agricultural machinery, thereby improving productivity and income.

Educational training programs: The Agricultural Machinery Research Laboratory can organize farmer training courses and technical training programs to teach farmers how to correctly use and maintain agricultural machinery equipment, as well as adapt to new technologies and operational skills. These educational training programs help enhance farmers' technical skills, enabling them to more effectively apply agricultural machinery and increase productivity.

Provision of consulting services: The Agricultural Machinery Research Laboratory can provide technical consulting services to address farmers' questions regarding the use and maintenance of agricultural machinery. By offering professional guidance and advice, the laboratory helps farmers better address technical challenges, ensuring the proper operation and maximized utilization of agricultural machinery equipment.

Overall, besides developing new agricultural machinery equipment, the Agricultural Machinery Research Laboratory can assist farmers comprehensively through agricultural machinery subsidy programs, educational training programs, and provision of consulting services, aiming to enhance productivity and technical skills among farmers and promote agricultural modernization and sustainable development.

Question: What are the steps and methods for research and development of agricultural machinery? Can you give an example?

answer:

The research and development process and methods for agricultural machinery typically include the following main steps:

Needs analysis: Initially, researchers communicate with farmers and agricultural producers to understand their needs and challenges. This can be done through field visits, surveys, and other methods.

Material analysis: Researchers conduct material analysis on the crops involved in the target agricultural machinery to determine suitable materials and processes.

Literature review: Researchers study existing relevant technologies and machinery through literature reviews and studies of established practices to identify aspects that can be utilized.

Innovative design: Based on the identified needs and literature review, researchers engage in innovative design to propose new concepts and solutions for agricultural machinery.

Simulation and testing: New designs of agricultural machinery undergo testing using computer simulations, laboratory experiments, etc., to verify their performance and feasibility.

Improvement and optimization: Based on the results of simulations and testing, agricultural machinery is improved and optimized to enhance its performance and reliability.

Practical application: The improved agricultural machinery is tested in real-world applications to observe its performance in actual agricultural production.

Monitoring and feedback: Through endurance testing and observation of usage by different farmers, researchers monitor the operation of agricultural machinery in practical applications, collect feedback, and use it as a basis for further improvements.

In summary, the process involves a series of iterative steps from needs analysis to practical application, with continuous monitoring and feedback loops to refine and improve agricultural machinery.

Example: In 2017, the Agricultural Machinery Research Laboratory received a task from the local agricultural association, which presented the need for mechanization in taro planting. Due to the planting season for taro falling between December and January each year, coinciding with the coldest weather, and considering that taro fields are typically flooded, it was often difficult to find sufficient laborers for planting, leading to severe labor shortages.

To address this issue, there was an urgent need to develop a specialized taro planting machine to streamline the planting process and make it easier to find workers for assistance. Initially, the research team engaged in extensive communication with farmers to understand the labor requirements and challenges involved in taro planting. Subsequently, they conducted a physical analysis of taro seedlings to select suitable materials and manufacturing methods. Following this, they conducted a thorough literature review to understand existing relevant technologies and designs.

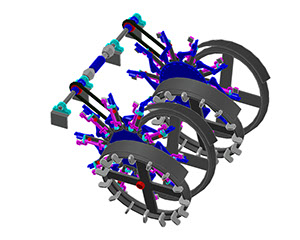

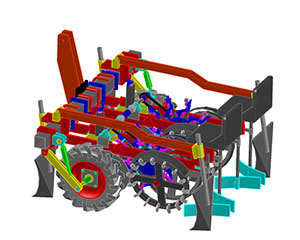

During the innovative design phase, they utilized 3D modeling for simulated analysis to evaluate the feasibility of different approaches. Next, through computer simulations and laboratory testing, they assessed the performance and feasibility of the machine. Based on the test results, key components were produced using 3D printing technology, and field trials were conducted to simulate actual operations.

Through multiple iterations of refinement and field testing in various locations, and through dialogue with taro farmers from different regions, the taro planting machine underwent continuous improvement and optimization. Eventually, the specialized taro planting machine successfully completed field application testing. It was granted a patent in 2019 and received the Silver Award in the 2020 National Innovation and Invention Awards.

Information and picture sources:Provided by Agricultural Machinery Research Laboratory

Changhua County Ming Lun junior high school, Taiwan.

Ming Lun Junior High School 2024 Cyber Fair